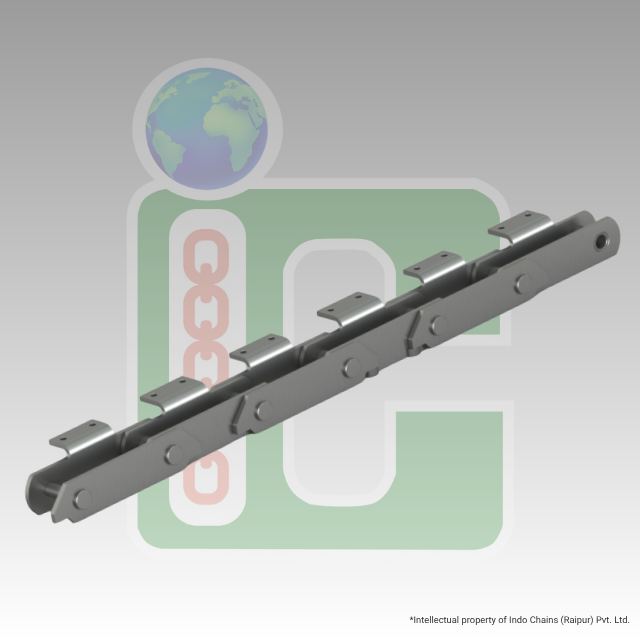

Drag Conveyor Chain

Price 7000.0 INR/ Meter

Drag Conveyor Chain Specification

- Material

- Stainless Steel

- Type

- Incline and Decline Conveyor

- Size

- As per requirement

- Structure

- Chain

- Product Type

- Drag Conveyor Chain

- Resistant Feature

- Heat Resistant

- Warranty

- Yes

- Usage & Applications

- Industrial

Drag Conveyor Chain Trade Information

- Minimum Order Quantity

- 10 Meter

- Delivery Time

- 16 Week

About Drag Conveyor Chain

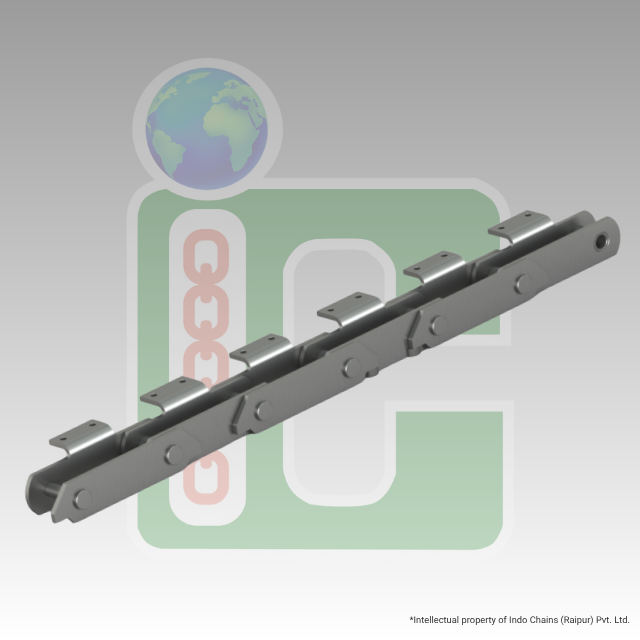

We are enlisted as affluent manufacturers, exporters and suppliers of top-notch quality Drag Conveyor Chain. These conveyor chains are made in accordance with the prevailing regulations of this domain. An optimum quality magnet is used in its fabrication so as to attain maximum dragging efficiency. The chain offered by us is used to separate the debris from the emulsion solution. With the aid of our highly experienced and prompt carriage & freight personnel, we have been able to deliver Drag Conveyor Chain to clients' ends.

Quality Features:

- Noiseless operation

- Optimum drag capacity

- Sturdy construction

- Longer service life

Technical Details:

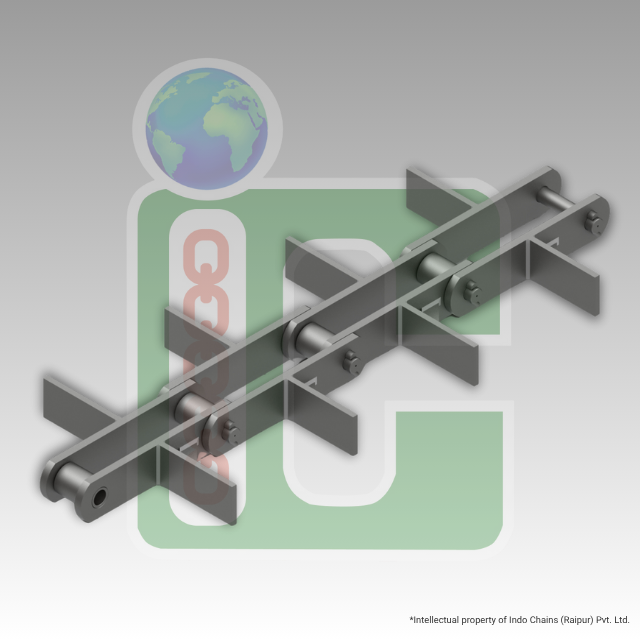

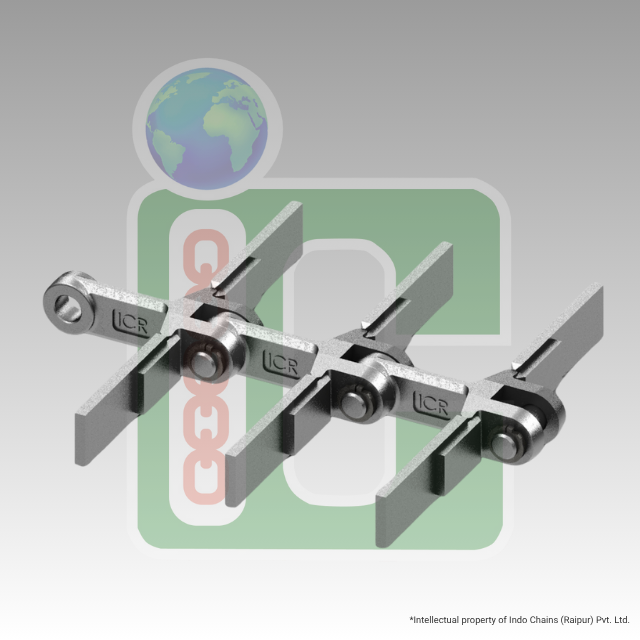

- Fork Link Chains for Conveyors & Besta Feeder

- Our fork link chains are used for conveyors to convey, distribute, feed, and extract bulk materials under various conditions. Whether horizontal, inclined or vertical conveyor systems are there.

- Our links are drop die forged to ensure maximum strength and breaking load. Our chains can be used for the movement of cement clinker, ash handling, limestone powder, slag handling, and rejects, among other applications.

- We manufacture fork link chains in various sizes, with pitches of 142mm, 175mm, 200mm, and 250mm, among others, as well as according to customer specifications.

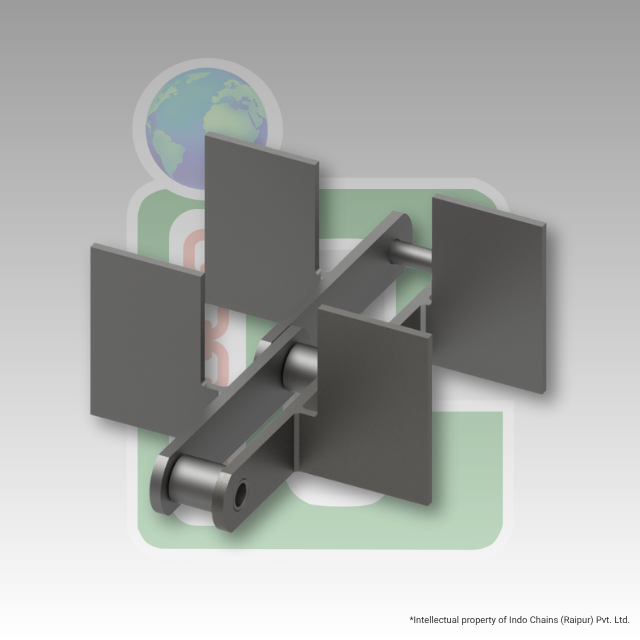

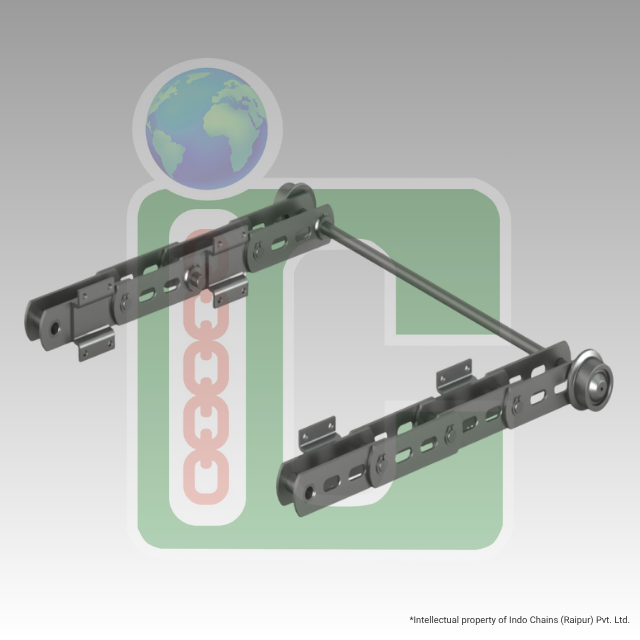

Heavy Duty Chains for Drag Conveyors

In the cement, limestone and gypsum industry, the heavy-duty drag chain conveyor is used for crushed limestone or for sticky raw material like chalk, gypsum, marl, clay or raw coal. Heavy-duty drag chains are equipped with different types of attachments and specially designed scrapers for transporting sticky materials. Our chains are available in various sizes, depending on the working load, ranging from 10 tons to 1000 tonnes per hour.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Conveyor Chains Category

Flow Conveyor Chain

Price 6000.0 INR / Meter

Minimum Order Quantity : 10

Material : As per customer requiement

Product Type : Flow Conveyor Chain

Color : steel grey

Usage & Applications : Industrial

Deep Pan Conveyor Chain

Price 5000.0 INR / Meter

Minimum Order Quantity : 10

Material : Stainless Steel

Product Type : Deep Pan Conveyor Chain

Color : Golden

Pan Conveyor Chain

Price 5000.0 INR / Meter

Minimum Order Quantity : 30

Material : Stainless Steel

Product Type : Conveyor Chain

Color : Blue

Deep Bucket Conveyor Chain

Price 4999.0 INR / Meter

Minimum Order Quantity : 30

Material : Stainless Steel

Product Type : Deep Bucket Conveyor Chain

Usage & Applications : Industrial

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese